Amal atmospheric injectors for propane, butane and natural gases

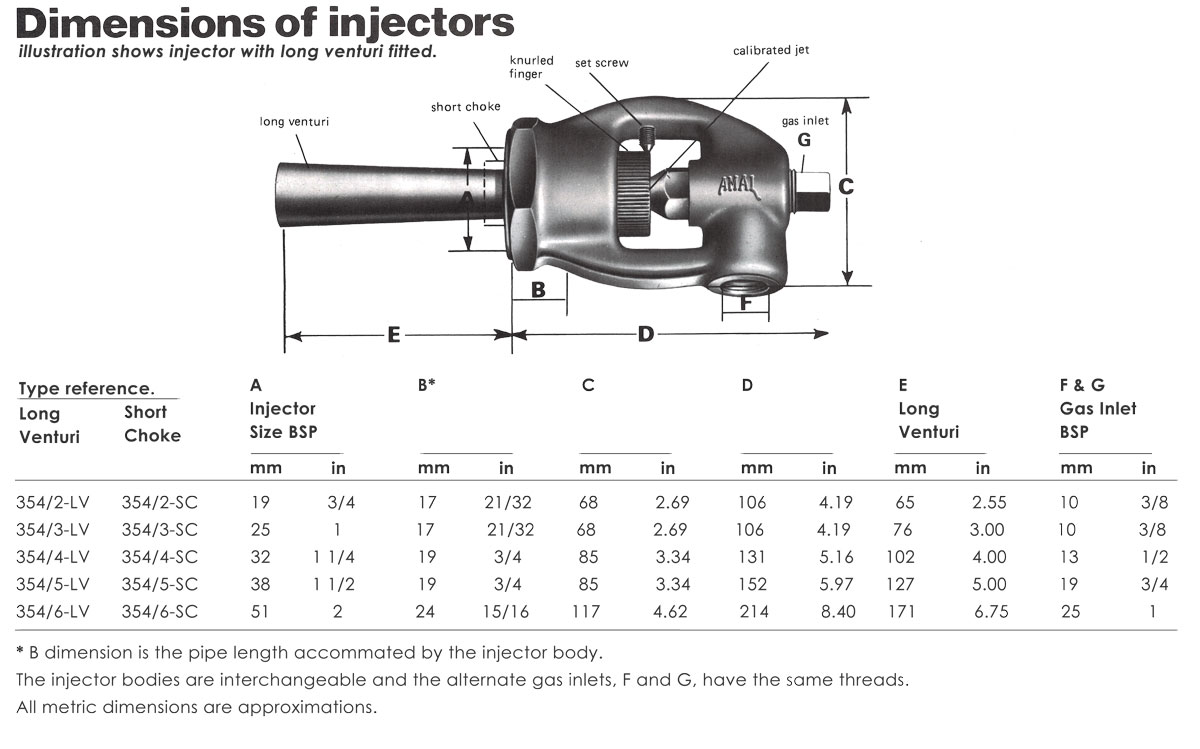

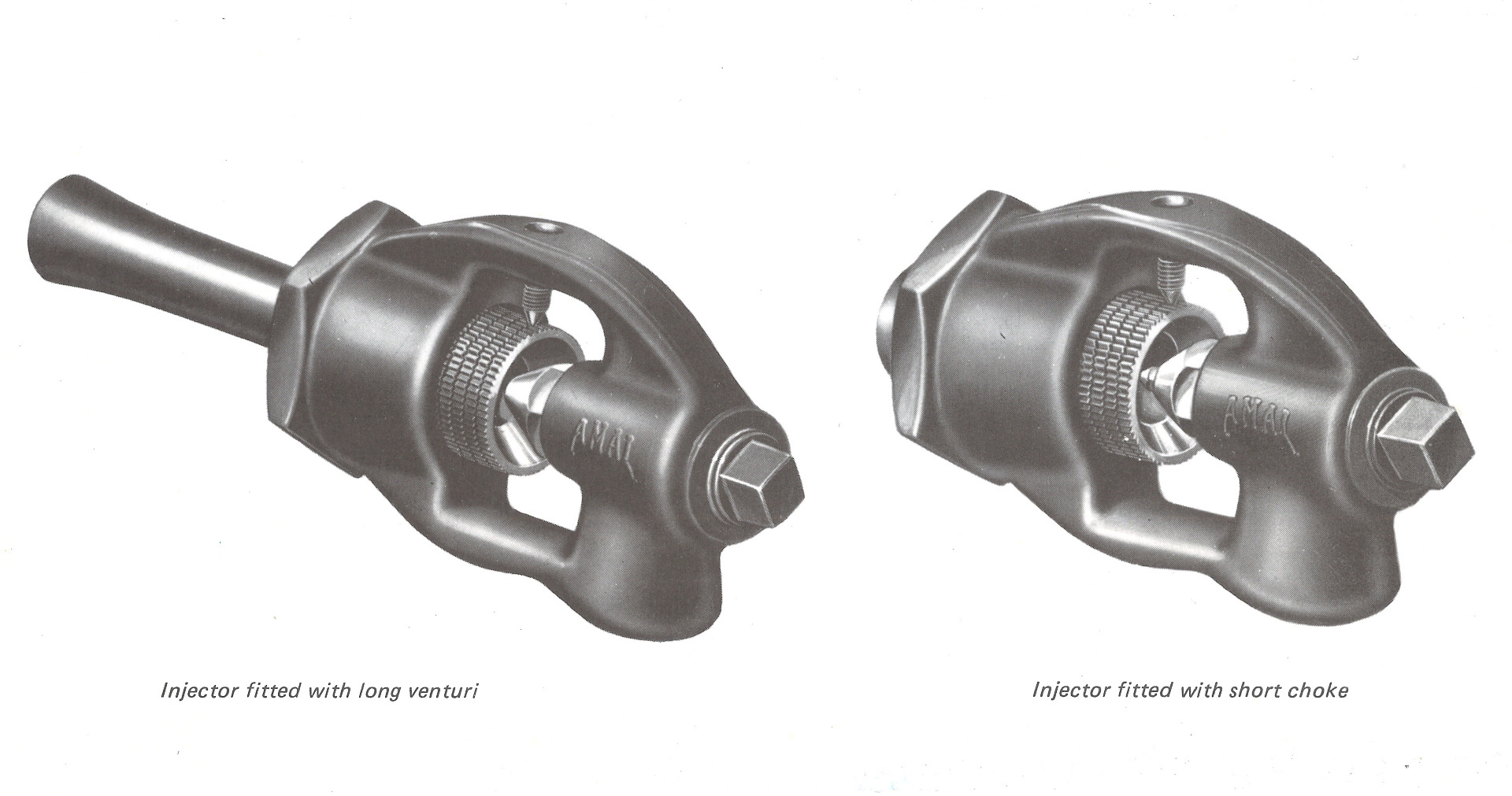

Amal atmospheric injectors combine robust construction with high performance in providing ideal gas/air mix for a wide range of burner applications. Manufactured from aluminium all the injectors come fitted with calibrated jets and either short chokes or long venturis depending on the specified application.

Amal calibrated jets enable the injectors to meet a specified consumption of gas at a given pressure. Accurate regulation of the primary air supply is provided by fine adjustment of the venturi or choke, giving a good 'turn down' and a range of flames from sharp to soft. The design of the injector also allows an alternative position for the gas inlet.

Gas injectors are a precise means of mixing specific volumes of gas with a required air supply to provide a flammable gas/air mixture. They allow the gas flow to be accurately controlled by means of a calibrated jet so that the rate of flow is known at any gas pressure. To accommodate different applications an adjustable choke or venturi controls the amount of air mixing with the gas.

Burner Systems

Various burner systems can be made by attaching Amal gas injectors to customers own burner bars or rings. To ensure correct mixing of the gas and primary air the distance between the injector and the flame nozzle, or the nearest burner port in a drilled bar or ring, should be approximately:

Long venturi = Twelve times the bore of the pipe.

Short choke = Six times the bore of the pipe.

It is recommended that short choke injectors be used with drilled burner bars or rings and long venturis be used with open ended burners.

Propane and butane injectors

When burning liquid gas the suppliers should be consulted as to the maximum take off limit from the cylinder. If too much is taken off, the liquid gas in the cylinder will fall below its boiling point and no further evaporation of the gas will occur. The gas flow will then cease.

When using ordinary drilled burner bars, to burn propane or butane, the pressure at the injectors calibrated jet must not exceed 14in water gauge (35 m bars) otherwise the flames will 'blow off'.

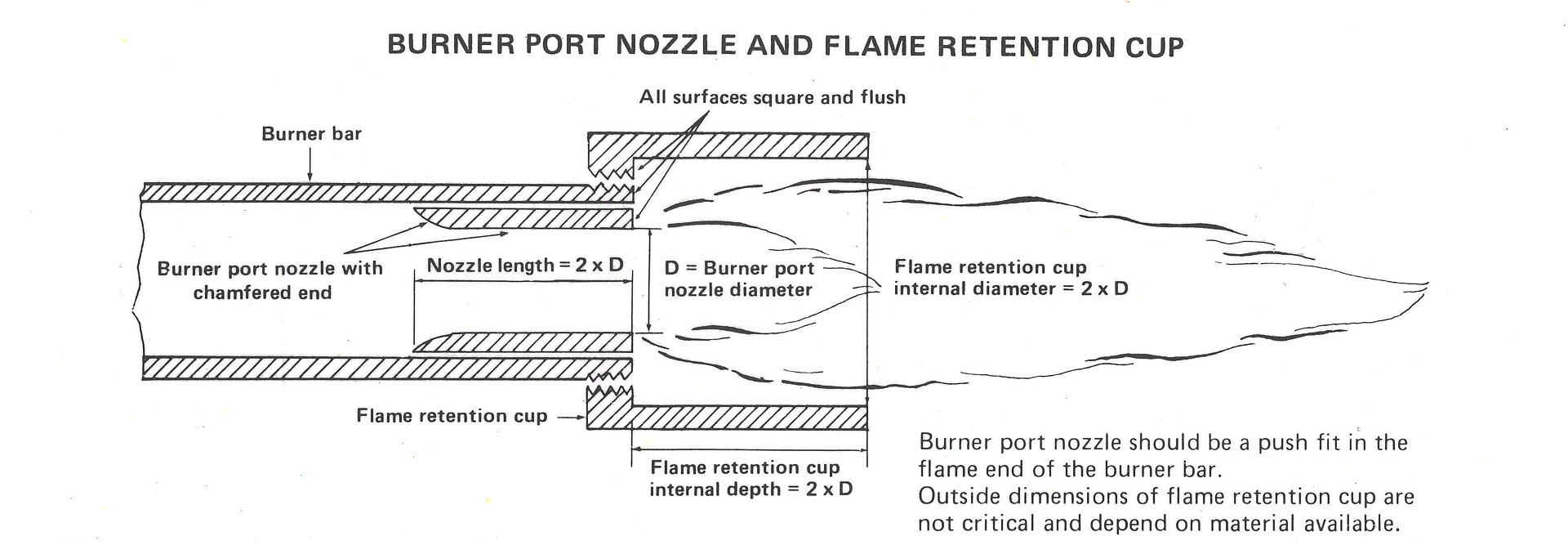

On open ended pipes, where the flame burns on a single nozzle and the gas pressure exceeds 14in water gauge (35 m bars), a flame retention cup should be used to give flame stability (see diagram below).

Setting short chokes or long venturis

Depending on the application, Amal injectors have either a short choke or long venturi to control the supply of air. Adjustment is best carried out as follows:

Aeration is usually at its maximum when the end face of the knurled finger portion of the choke or venturi is level with point of the set pin (see dimension of injector image). To reduce primary aeration; the throat should be screwed towards the calibrated jet. The same procedure is necessary to stabilise the flame should it tend to lift, particularly when the burner is cold.

It is impossible to predict the resistance of various burner ports making it necessary to adjust the choke position according to circumstances. Once set it can be fixed in position by he set screw.

Information in this article gives a practical guide to liberating specified volumes of gas and promoting primary air mixtures. The burner port areas suggested must only be regarded as a starting point. Amal cannot take any responsibility for their design and final adoption.

Prevention of 'blow off' from open ended burners

When the pressure of propane or butane passing through an injector exceeds 14in water gauge (35 m bars) there is a possibility of the flame being 'blown off' and extingguished. To prevent this from occuring a flame retention cup can be attached to the open ended burner as shown below.

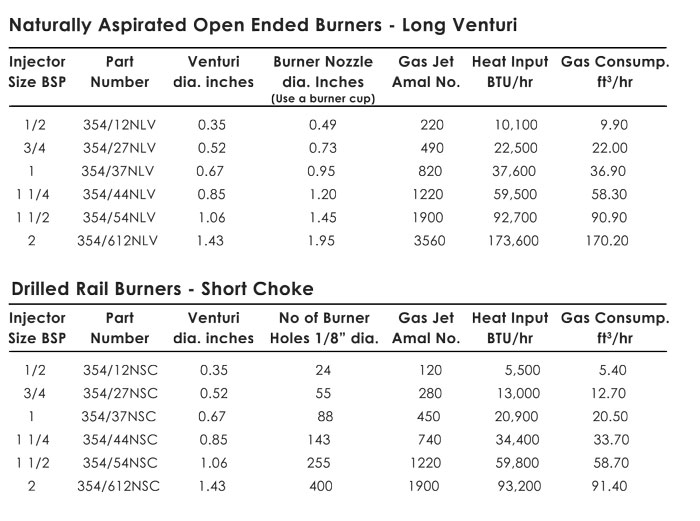

Injector selection

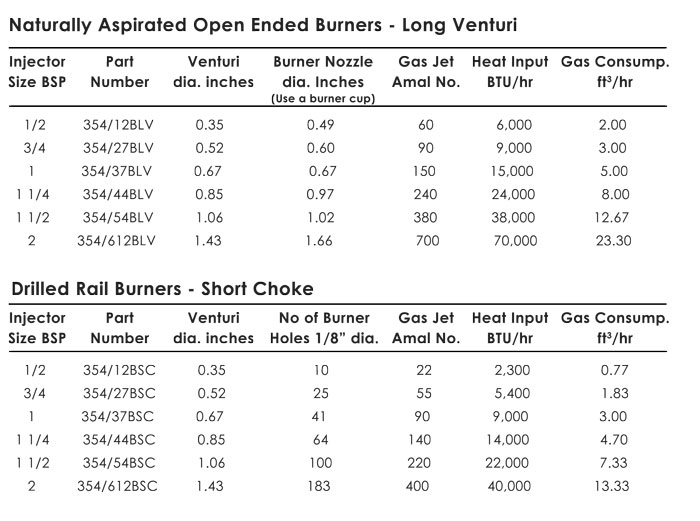

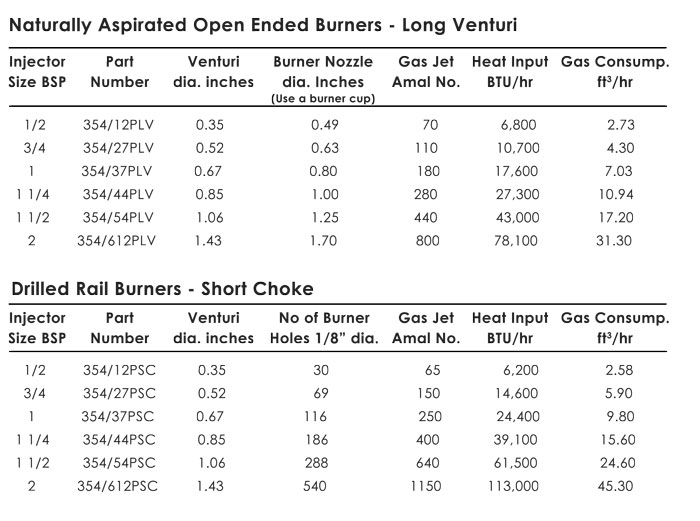

To supply the correct injector for a particilar application specift the BTU's/hr required and referring to the data tables below, the injector number (dependent on the diameter of pipe from the burner head), the jet number and whether a long venturi or short choke is required.

Injector data and specifications - Natural gas

Injector data and specifications - Butane gas

Injector data and specifications - Propane gas

For long venturis the above data is empirically derived and assumes:

Natural gas with SG 0.600, CV 1020 BTU/ft3, pressure 8 inch wg

Propane - SG 1.56 CV 2500 BTU/ft3, pressure 11 inch wg

Butane - SG 2.06, CV 3000 BTU/ft3, Pressure 11 inch wg